You put time and money into an epoxy garage floor expecting it to last, but cracks, peeling spots, or a slick surface can quickly change that. Hot tires lift the coating, Florida’s humidity creates bubbles, and stains make the finish look older than it should. Most of the time, the problem comes down to skipped prep or the wrong care routine.

The great news is you can avoid expensive do-overs. With the right prep, simple maintenance habits, and repair solutions, your floor can stay strong and sharp-looking for years and that’s exactly what you’ll find here.

Before You Install: Surface Prep Mistakes That Ruin Epoxy Floors

A strong epoxy garage floor starts with the right surface prep. When you cut corners here, the coating doesn’t bond, and the floor fails long before its time. Many homeowners ignore moisture issues, rough concrete, or stains, only to face peeling coatings and wasted money later.

The most common prep mistakes are:

- Skipping moisture testing. If you don’t test the slab with a plastic sheet, hidden vapor will break the bond and cause bubbling or peeling.

- Not mechanically grinding. Acid etching from DIY kits leaves uneven results. Diamond grinding gives you a properly prepared surface with better adhesion and a durable finish.

- Applying epoxy over oil stains or uneven spots. Oil or brake fluid left in the concrete prevents the epoxy system from sticking. Low areas create thin coat sections that wear out quickly.

After Installation: Common Maintenance Mistakes

Even a successful epoxy floor won’t last if you don’t care for it the right way. An epoxy coating is built for vehicle traffic and chemical resistance, but poor habits shorten its life. Hot tire pickup, scratches, and fading often come down to how you clean and maintain the surface.

The most common maintenance mistakes are:

- Power washing too aggressively. High pressure chips away at the coating and ruins the smooth finish.

- Using the wrong vacuum attachments. Hard bristles scratch the gloss and weaken the topcoat.

- Skipping resealing or UV topcoats. If you don’t reseal, sunlight breaks down the coating, leaving a floor that yellows and loses its showroom look.

Repairing Peeling, Bubbling, or Stained Epoxy Floors

Even with proper surface preparation, an epoxy garage floor can fail over time. Heat, moisture, or poor application often lead to peeling, bubbling, or stains that affect durability and appearance. Recognizing the signs early helps you decide whether repair or resurfacing is the better choice.

|

Signs of Coating Failure |

What It Means |

|---|---|

|

Peeling or flaking near hot tire pickup zones |

Bond between the coating system and concrete surface has weakened |

|

Bubbling or blistering |

Moisture under the slab is pushing up through the floor coating |

|

Discoloration or stains |

Chemical spills or skipped topcoat left the floor without protection |

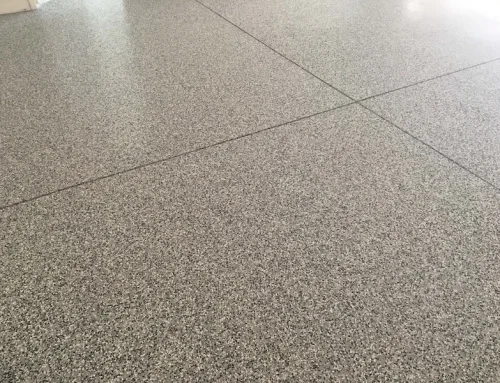

In many cases, spot repair is only a temporary fix. When large areas of garage floor epoxy show failure, resurfacing delivers better results. Resurfacing includes grinding down the previous coating, applying moisture-tolerant primers, and finishing with a stronger epoxy system. Creative Resurfacing Solutions uses diamond grinding, patching, and advanced flake systems to restore a smooth concrete base and create an easy-to-clean surface that looks new again.

Tips for Long-Lasting Epoxy Garage Floor Performance

Once a coating system is repaired or replaced, how you care for it makes the difference between a short lifespan and years of reliable use. Following a few simple steps helps your garage floor epoxy handle both light foot traffic and heavy vehicle traffic without losing its gloss.

- Use soft-bristle vacuums and neutral cleaners for routine care.

- Rinse with low-pressure water instead of harsh power washing.

- Reseal or apply UV topcoats every few years for added durability.

- Avoid storing chemicals or heavy equipment directly on the coating for extended periods of time.

- Keep the garage floor clear of moisture by checking for leaks or drainage issues.

CRS Garage Epoxy Floors Hold Up Better in Florida Homes

Florida’s climate is harsh on a garage floor epoxy. High humidity, sudden rain, and heavy vehicle traffic test the strength of any floor coating. Many homeowners see bubbling after one rainy season or slippery spots when summer storms roll in. Creative Resurfacing Solutions builds each epoxy garage floor to prevent those problems before they start.

- Custom prep. Every project includes mechanical grinding to open the concrete surface, patching to remove cracks or uneven spots, and moisture testing to avoid peeling later.

- Anti-slip options. Additives and flake systems improve traction, reducing the risk of slips when water is tracked in from the driveway.

- Humidity-resistant systems. Moisture-tolerant primers and high-solids epoxy stand up to Florida’s damp conditions, creating a strong bond and durable finish.

These steps ensure your garage floor epoxy looks sharp and stays safe, even when the weather doesn’t cooperate.

Protect Your Investment With CRS Epoxy Garage Floors

An epoxy coating can make a concrete surface smooth, durable, and easy to clean. But when shortcuts are taken, floors often peel, stain, or lose gloss far too soon. If you’ve dealt with a coating that lifted under hot tires or faded after one summer, you know how disappointing that feels.

Creative Resurfacing Solutions delivers epoxy garage floors built for Florida garages and commercial spaces. With proven surface prep, moisture control, and advanced coating systems, CRS helps you achieve a showroom-quality finish that handles daily use and local weather.

If you’re ready for a floor coating that holds up year after year, schedule a consultation today. The right prep and installation protect your investment and give you a floor you can count on.

Frequently Asked Questions

Can I vacuum my epoxy garage floor?

Yes, you can vacuum an epoxy garage floor, but use a soft-bristle or brush attachment to avoid scratching the coating. Avoid stiff bristles or metal edges that can dull the finish.

Can you pressure wash an epoxy garage floor?

Light pressure washing is safe, but avoid high settings that chip or lift the coating. A low-pressure rinse paired with a mild cleaner works best to protect the floor coating.

Why is my garage epoxy floor peeling?

Peeling often comes from poor surface preparation, hidden moisture in the concrete slab, or skipping a topcoat. Once the bond is broken, sections of the coating system lift under foot traffic or vehicle tires.

How often should I reseal my epoxy garage floor?

Most floors need resealing every three to five years depending on use and sun exposure. Resealing with a urethane or UV topcoat extends durability and keeps the surface looking like new.

Can hot tires damage my epoxy floor?

Yes, hot tire pickup is one of the most common issues. Tires heat up after driving and soften the coating, causing it to peel or leave marks if the epoxy system isn’t installed with proper prep and topcoat protection.